(2019-2025) Factory Automation & Industrial Controls Market CAGR Status, Industrial Analysis | Market Current Insights, Growth & Opportunities

July 03, 2020

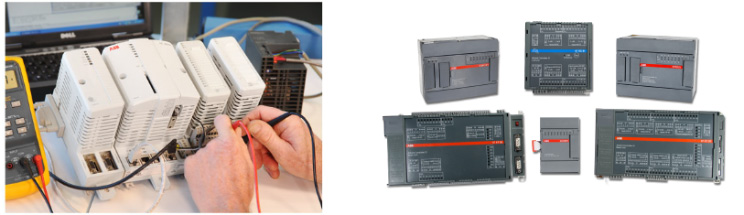

Factory Automation & Industrial Controls Market Analysis Report Forecast 2018-2025 TheFactory Automation & Industrial Controls Market report focuses on the global andregional market, providing information on major players like manufacturers, suppliers, distributors, traders, customers, investors and etc., major types, major applications and etc. Data type includes capacity, production, Factory Automation & Industrial Controls market share, price, revenue, cost, gross,gross margin, growth rate, consumption, import & export,etc. Industry chain, manufacturing process, cost structure, marketing channel are also analyzed in this report. Get Sample of Factory Automation & Industrial Controls Market Report @ https://www.360researchreports.com/enquiry/request-sample/12805204 Short Description for Factory Automation & Industrial Controls Market: “Factory automation implies a set of technologies and automatic control devices to enhance the productivity and quality of products and simultaneously decrease the production cost. Also known as industrial automation, it minimizes human intervention in the industry and ensures a superior performance as compared to humans. It comprises the use of computers, robots, control systems, and information technologies to handle industrial processes. The global Factory Automation & Industrial Controls market is valued at xx million US$ in 2017 and will reach xx million US$ by the end of 2025, growing at a CAGR of xx% during 2018-2025. “ Global Factory Automation & Industrial Controls market competition bytop manufacturers, with production, price, revenue (value) and Factory Automation & Industrial Controls Market share for each manufacturer;the top players including ABB Emerson GE Honeywell Mitsubishi Omron Rockwell Schneider Electric Siemens Yokogawa Kuka Keyence Fanuc Bosch Rexroth Fuji Electric Endress+Hauser Hitachi , And Other